Steel Infill Panels - Questions

Table of ContentsGetting My Double Glazed Door With Side Panels To WorkThe Best Guide To Perforated Metal Infill PanelsThe smart Trick of Timber Frame Infill Panels That Nobody is Discussing

Constant metal sill flashing at the base of the curtain wall protects the wall framing listed below from leakage through the curtain wall. Sill flashing ought to have upturned end dams and completely sealed corners. Intermediate horizontal ought to be wept to the outside and prevent water from draining onto the head of the glazing system below.Locate setting blocks regarding not obstruct water drainage from the glazing pocket. Offer anti-walk blocks at the jambs of the glazing units. Blocks need to be gapped 1/8-inch from the edge of the glazing unit. Note: the following U-series details are thanks to The Exterior Group This elevation reveals a typical unitized curtain wall assembly hung from the edge of the flooring slab.

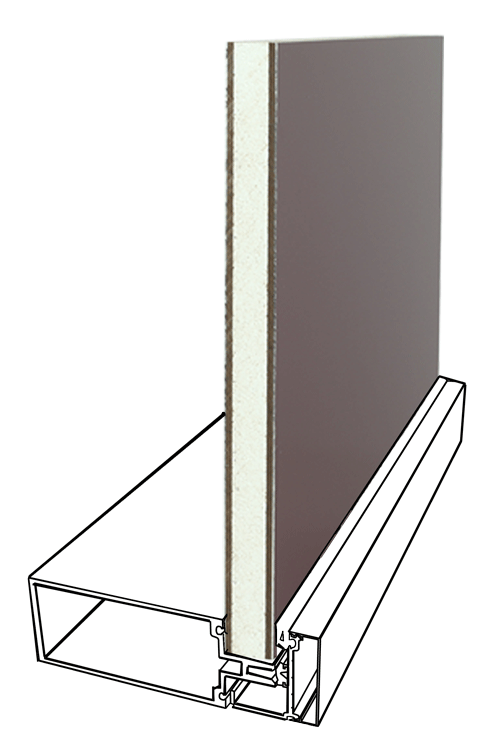

The system shown is composed of vision glazing and a glazed spandrel shadow box with an insulated back pan. A constant vertical gasket provides the primary weather condition seal at the pressure equalized rainscreen zone of the assembly. Foam glazing tape weather seal is discontinuous at horizontal panel joints to attain pressure equalization in between weather condition and air seals at vertical system joints.

The units are gotten in touch with a field applied splice sleeve that consists of an index clip to line up the next unit above the joint horizontally as it is being set. Glazing pocket weeps are secured from wind-driven rain and pressure by a glazing trim cover containing weep slots in the bottom which are balanced out from the sill glazing pocket weep slots and the glazing setting obstructs at glazing panel quarter points.

Gasket height should represent the curtain wall design pressure. Outside cover splice sleeves are set up at the face of the stack joint throughout system field setup. Systems are created and installed with horizontal and vertical clearance spaces to allow for differential motion and accommodate construction tolerances. Pressure equalized rainscreen gaskets form a primary weather seal at the face of the unitized vertical stack joint in line with the horizontal rainscreen gasket at the unit sill listed below.

Spandrel glass adapters are used to lower the depth of the glazing pocket to accommodate lowered profile of spandrel glass. Spandrel glass adapters need to be totally bedded in sealant and incorporated with glazing pocket corner seals to avoid water leakage from glazing pocket to building interior. System measurement of mating head and sill extruded profiles permits specified floor to flooring deflection at the stack joint.

Some Known Facts About Railing Infill Panels.

Intermediate horizontals stop at the face of the vertical system jamb members at each end. Units are hung from the top or face of the surrounding floor or building structure utilizing mated brackets and field used bolts with a minimum of clearance for access and assembly. All connections and brackets situated within the units insulated or main weather seal zones are sealed with proper sealant materials during field installation.

, like clever windows, control visible light transmittance by employing electrochromic or photochromic glass finishings; see the conversation in Glazing., which utilize an aerated space in between the inner and external walls are unusual in the U.S., but have actually been constructed in Europe and Asia where energy costs are much higher.

During the heating season, the area serves as a buffer in between the outside and interior, and can be used to temper outdoor supply air. During the cooling season, warm interior air is tired into the area. There is currently discussion amongst structure science professionals that, a minimum of for cold climates, a more economical method of attaining look at here now energy savings might be through the use of drape walls with high (over R-6) insulating worths.

AAMA 501. 4 & 501. 6 Advised Static Test Technique for Evaluating Curtain Wall and Shop Systems Subjected to Seismic and Wind Caused Interstory Drifts and Suggested Dynamic Test Approach For Identifying the Seismic Drift Causing Glass Fallout from a Wall System Building Envelope Design GuideGlazing, Structure Envelope Style GuideWindows, See appropriate sections under applicable guide requirements: Unified Facility Guide Specifications (UFGS), VA Guide Specs (UFGS), Federal Guide for Green Construction Specifications, MasterSpec KEEP IN MIND: Photographs, figures, and drawings were provided by the initial author unless otherwise kept in mind. stainless steel infill panel.

TabulationThe Main Principles Of Large Double Glazed Glass Panels The Very Best Guide To Glazed Window PanelsGlazing Infill Panels for DummiesAnalyze This Report about Glazing PanelGlazed Wall PanelsUltimately silicone sealants or glazing official statement tape were replacemented for the glazing compound. Some styles included an external cap to hold the glass in position and to safeguard the integrity of the seals.

Rumored Buzz on Stainless Steel Infill Panel

Glazed Window PanelsLudwig Mies van der Rohe's glazing panel retainer drape wall surface area is just one of among the most vital aspect of his structure design. Mies initially started prototyping the curtain wall in his high-rise domestic structure designs along Chicago's lakeshore, accomplishing the look of a drape wall at famed 860-880 Lake Coast Drive Apartments.

Customized types can be made as well as made with relative simplicity - double glazed door with side panels. Glazed Panel WindowThe large bulk of ground-floor drape wall surface areas are set up as lengthy items (referred to as sticks) in between floorings up and down and in between upright members flat. Mounting members might be made in a shop, but setup and likewise glazing is usually performed at the jobsite.